Introduction

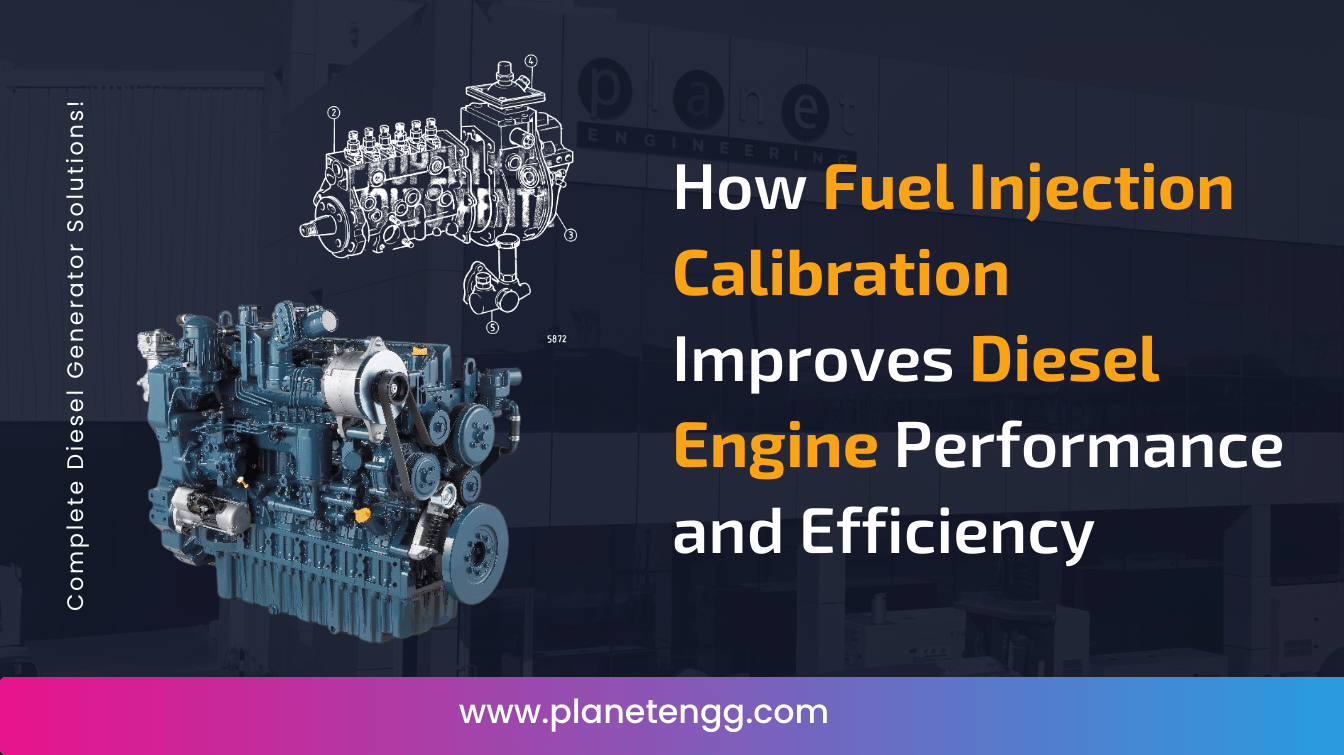

Planet Engineering Fuel Injection Calibration Center & Diesel Component Repairer in Qatar provides precision-driven calibration and repair services critical to diesel engine performance, fuel efficiency, and operational reliability across industrial sectors.

Role of a Fuel Injection Calibration Center in Diesel Engineering

- Importance of accurate fuel delivery

- Impact on combustion efficiency and emissions

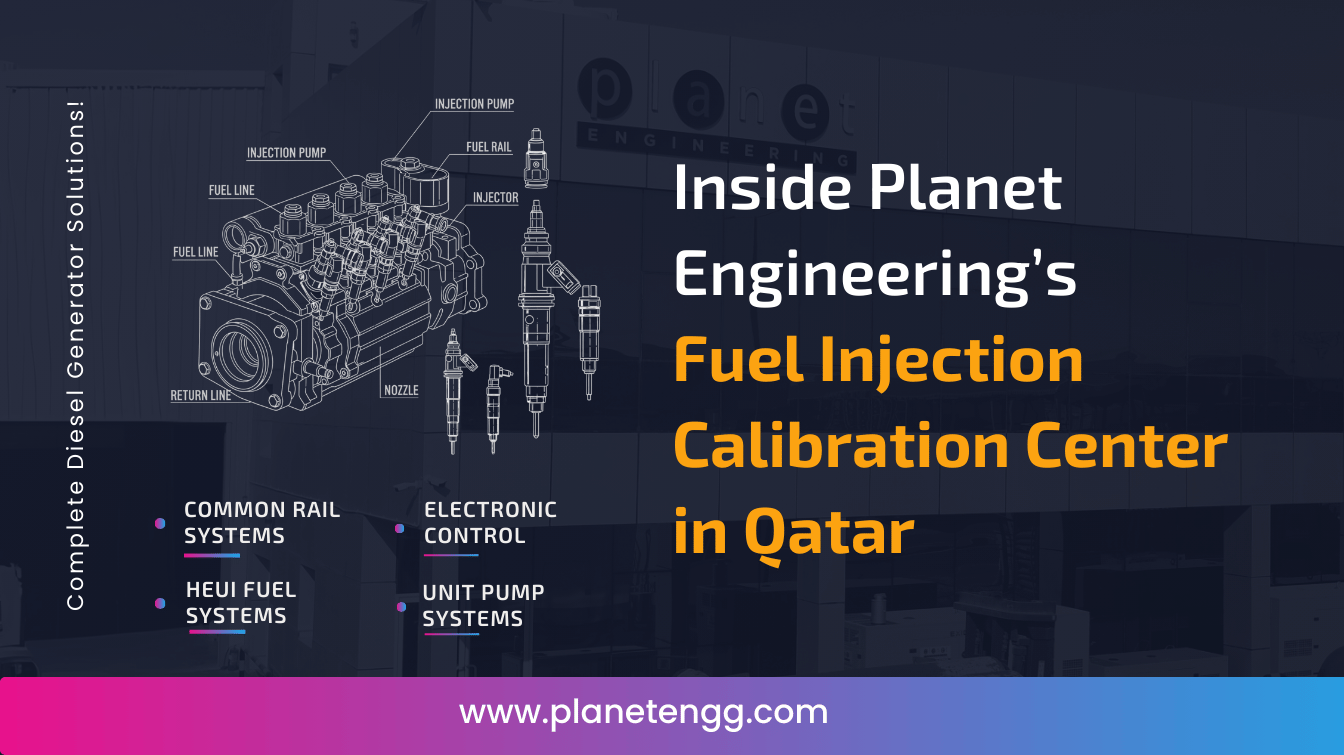

Fuel Injection Systems Supported

-

Mechanical Fuel Injection Systems

-

Electronic Fuel Injection Systems

-

Common Rail Diesel Systems

Diesel Components Serviced and Repaired

- Injectors and nozzles

- Fuel injection pumps

- Pressure control valves

- Governors and control units

Calibration Process and Technical Workflow

- Inspection and diagnostics

- Bench testing and flow analysis

- Precision calibration and validation

- Performance verification

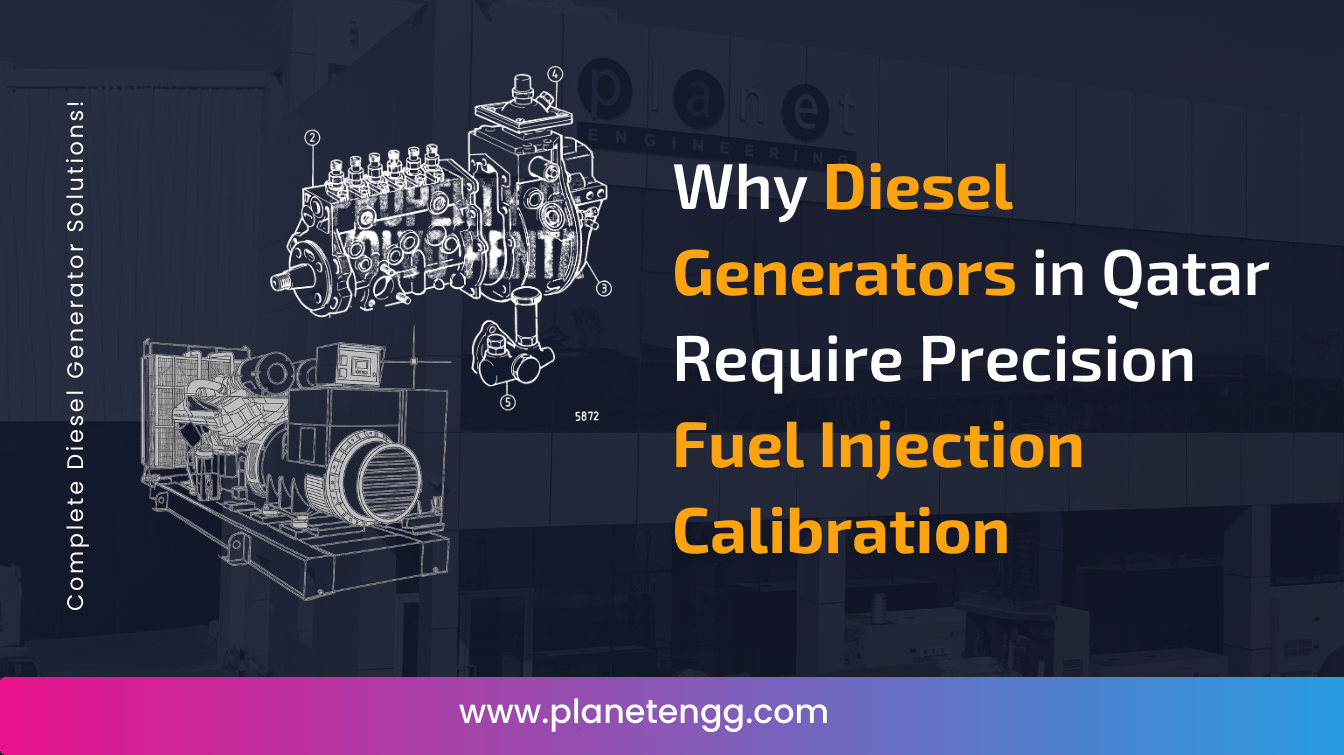

Why Fuel Injection Calibration Is Critical in Qatar

- High ambient temperatures

- Continuous-duty generator operation

- Fuel quality variations

Quality Standards and Technical Compliance

- OEM-aligned calibration benchmarks

- Documentation and traceability

- Repeatability assurance

Conclusion

Planet Engineering Fuel Injection Calibration Center & Diesel Component Repairer in Qatar delivers technically disciplined solutions that restore diesel engines to optimal operating condition while reducing lifecycle costs.

FAQs

Q1: What is fuel injection calibration?

Fuel injection calibration is the precise adjustment of fuel delivery parameters to restore correct combustion and engine performance.

Q2: When should diesel injectors be calibrated?

Calibration is recommended during performance loss, high fuel consumption, smoke issues, or scheduled preventive maintenance.

Q3: Is calibration better than replacement?

Calibration is often more cost-effective and technically sufficient when components are within serviceable limits.

Q4: Does calibration improve fuel efficiency?

Yes. Proper calibration directly improves combustion efficiency and reduces fuel wastage.